- Ahmedabad - 382445. Gujarat, (India).

- info@vineetprocessequipment.com

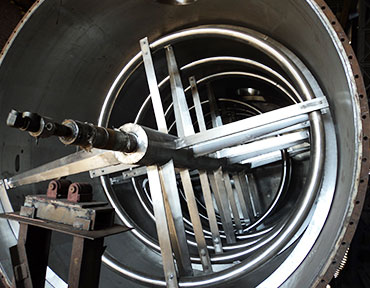

Sugar Crystallizer

Brief introduction

The crystallizer is closed cylindrical structure, both ends of the cover is installed packing gland and reducer. Tank wall has swirl cooling water jacket. Tank center is set with hollow shaft to fix the cooling coil and the stirring spiral belt, the ends of the shaft head equipped with machine-sealed rotary joint, and with the role of cooling water circulation.

Working principle

Horizontal Crystallizer is equipment for crystal precipitation by cycle water cooling. The saturated crystal filtrate will be injected from the feed nozzle on top of the crystallizer and get cooling gradually by the combined cooling effect of cycle water in the helical pipe and cylinder interlayer during work process. The crystal filtrate attaches around the crystal and gradually grows bigger. After certain time the crystal filtrate gets less and crystal gets bigger gradually, then the crystallization process is complete. The crystallization process is running at atmospheric pressure, the crystallization temperature is determined by the crystallization process, and the crystallization process is non-continuous. Its outstanding features are the simple structure, energy saving and comfortable operation.